Global Efficiency Optimization Strategies for Geothermal Power Plants by PETROXIN

Overview

PETROXIN Ltd is working toward converting mature oilfields into geothermal power plants, showcasing the potential of geothermal energy for sustainable electricity production. This report outlines the work completed so far and the strategies PETROXIN will explore to improve efficiency. While significant progress has been made, PETROXIN acknowledges that much more investment and effort are required to optimise performance and maximize energy output.

In this example, PETROXIN used an oilfield producing 500,000 barrels of water per day to demonstrate the feasibility of geothermal energy extraction and the necessary calculations for energy production.

Work Completed by PETROXIN Ltd So Far

1. Geothermal Resource and Power Calculation Example

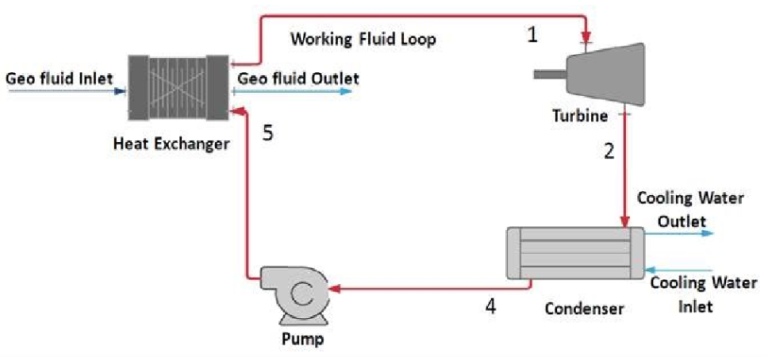

PETROXIN applied its methods to an oilfield producing 500,000 barrels of water per day (approximately 79,493.5 cubic meters per day). The geothermal potential of the water, assumed to be at an inlet temperature of 80°C and an outlet temperature of 50°C, was calculated to demonstrate how much electricity could be generated using an Organic Rankine Cycle (ORC).

Key Parameters:

- Inlet temperature: 80°C

- Outlet temperature: 50°C

- Flow rate: 500,000 barrels per day

- Conversion efficiency: 4%

Step 1: Thermal Energy Calculation

The thermal energy available from the co-produced water was calculated using the relevents formulas.

The thermal power available from the water was calculated to be:

Q=115.38MW

Step 2: Electrical Power Output with 4% Efficiency

Assuming an ORC efficiency of 4%, the electrical power output is:

Electrical Power=4.62MW

Step 3: Annual Energy Production and Revenue

For continuous operation over a year (24 hours per day, 365 days per year):

- Energy produced per day: 4.62 MW × 24 hours = 110.76 MWh/day.

- Energy produced per year: 110.76 MWh/day × 365 days = 40,427.74 MWh/year.

At an electricity price of $0.10 per kWh, the estimated annual revenue from electricity generation is:

Annual Revenue=$4,042,774per year

Strategies for Efficiency Improvement by PETROXIN Ltd

While the calculations show a promising potential for electricity generation, PETROXIN recognizes that the efficiency of the system can be greatly improved. PETROXIN is committed to investing in research and development to optimize the geothermal power plant's performance. Below are key areas where PETROXIN plans to focus its efforts to improve efficiency.

1. Supercritical Fluids in ORC Systems

PETROXIN is exploring the use of supercritical fluids, such as supercritical CO2, to enhance the efficiency of the ORC system. While promising, this technology will require significant investment and development to determine its practical benefits in different geothermal settings.

- Supercritical ORC: PETROXIN will continue to investigate supercritical ORC systems, recognizing that this technology could offer substantial efficiency gains in the future, but more research and field trials are needed.

2. Thermoelectric Generation

PETROXIN is evaluating the potential of thermoelectric generators (TEGs) to convert temperature differences directly into electricity. These devices would work alongside the ORC system to capture additional power from waste heat that might otherwise go unused.

- Hybrid Systems: The integration of ORC and TEG systems may allow PETROXIN to optimize energy capture, although this approach is still in the experimental stage and will require further investment.

3. Heat Pump Integration

PETROXIN is looking into integrating heat pumps to preheat the working fluid before it enters the ORC system, reducing the load on the geothermal source and improving the overall energy efficiency of the plant.

- Heat Pumps: This technology has potential, but PETROXIN will need to explore how best to integrate it into existing systems without significantly increasing costs or complexity.

4. Cascade Utilization of Geothermal Energy

PETROXIN is focusing on cascade utilization of geothermal energy, where the geothermal fluid is used for multiple purposes. After generating electricity, the remaining heat can be repurposed for applications such as district heating, agriculture, or industrial processes.

- Maximizing Energy Use: PETROXIN plans to explore options for using the remaining heat in various sectors, although this will depend on local conditions and infrastructure.

5. Geothermal-Solar Hybrid Systems

PETROXIN is considering the integration of solar thermal energy with geothermal systems to improve efficiency. Solar thermal collectors could preheat the working fluid, increasing the overall energy extraction from the geothermal system.

- Hybrid Systems: While the concept is promising, PETROXIN will need to carefully assess the costs and benefits of implementing this system in regions where solar resources are abundant.

6. Enhanced Geothermal Systems (EGS) Optimization

PETROXIN is exploring Enhanced Geothermal Systems (EGS) to increase heat extraction in locations with insufficient natural permeability. By artificially increasing the flow of fluids through hydraulic fracturing or injection, PETROXIN can access additional geothermal heat.

- EGS Development: While EGS offers a solution to geothermal challenges in certain regions, it requires further investment and testing to ensure long-term sustainability and viability.

7. Binary Systems with Multiple Stages

PETROXIN is investigating the use of binary systems with multiple stages, which can extract energy across a broader range of temperatures. High-temperature fluids can drive one turbine, while lower-temperature fluids power a second, improving overall efficiency.

- Flash-Binary Systems: This approach is being considered, but PETROXIN will need to conduct more research to determine its feasibility for specific projects.

8. Variable Load Optimization

PETROXIN is developing systems for variable load optimization, which will adjust power output based on demand, resource availability, and other factors. By dynamically managing load, the plant can operate more efficiently.

- Smart Load Management: Implementing smart systems for real-time monitoring and control will be a key area of focus to maximize energy efficiency.

9. Geofluid Reinjection Optimization

PETROXIN is optimizing the process of reinjecting cooled geothermal fluids to maintain reservoir pressure while minimizing thermal interference. Proper reinjection will help sustain long-term heat extraction.

- Reinjection Strategies: PETROXIN will focus on improving well placement and reinjection techniques to avoid cooling the production wells too quickly.

10. Waste Heat Recovery

PETROXIN is considering the use of waste heat recovery systems to capture remaining low-grade heat after electricity generation. This waste heat can be repurposed for district heating, industrial applications, or other uses.

Conclusion

PETROXIN Ltd has taken the first steps in demonstrating the potential for geothermal energy extraction from oilfields, as seen with the 500,000 barrels-per-day example. While initial calculations show that the system could produce 4.62 MW of electricity and generate $4.04 million in annual revenue, PETROXIN is aware that this is just the beginning.

Significant investments in technology, infrastructure, and research will be required to improve efficiency. PETROXIN is committed to continuing its work in areas like supercritical ORC systems, hybrid energy solutions, Enhanced Geothermal Systems (EGS), and waste heat recovery, acknowledging that each step forward will contribute to building a more efficient, sustainable energy future.

While the journey ahead is challenging, PETROXIN is dedicated to finding the best solutions to make geothermal energy a viable and efficient option in oilfields across the globe

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.